Collection: Schunk Planos

Description

Advantages – Your benefits

-

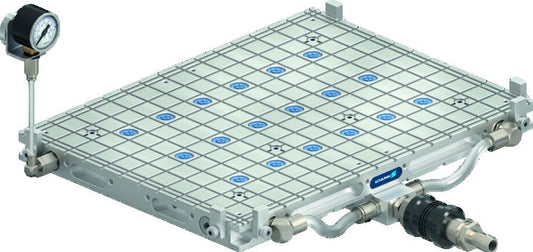

High-strength aluminum base body

Distortion-free clamping of flat and thin components -

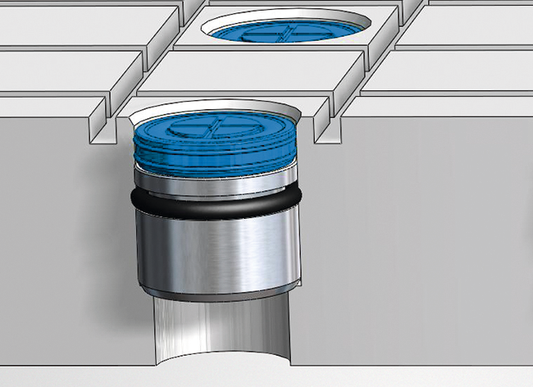

Pressure gauge as standard

Enables continuous vacuum monitoring on the workpiece -

Connection set with manual slide valve

For optimum vacuum supply and comfortable working -

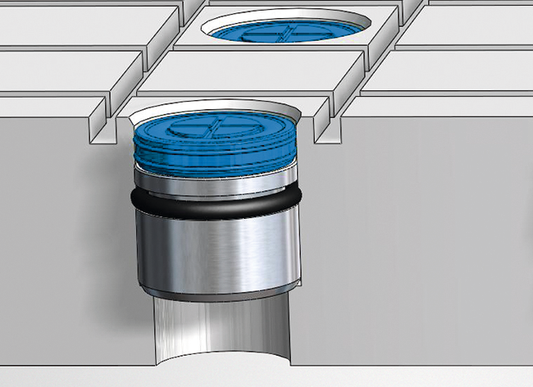

Improved vacuum guide

Process-reliable clamping due to high clamping forces -

Patented friction islands as an option

Increase in the holding forces by up to 30% without deformation of the workpiece -

Mechanical back stops attached at the side

Simple positioning of the workpiece and additional absorption of shearing forces -

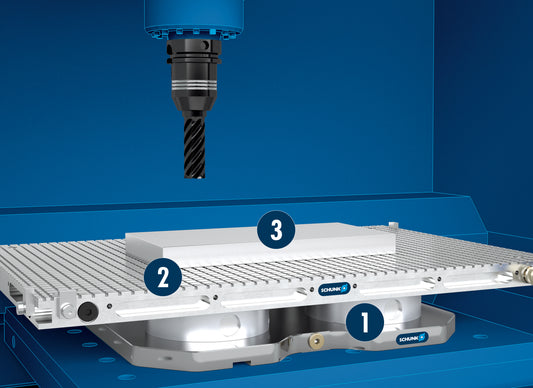

Support plate in combination with suction cups and elastomer mat

Enables 5-sided machining and simple production of cut-outs and recesses -

Modular system

Flexible design of the workpiece -

Adaptation on conventional clamping devices possible

Simple and fast initial operation of the matrix plate on the machine table -

VERO-S interface

Versatile range of combinations due to the VERO-S modular system. Even shorter set-up times

Options and special information

-

Short set-up times – High holding forces – Maximum precision

PLANOS matrix plates from SCHUNK clamp flat workpieces and workpieces with a flat bottom reliably and quickly. They ensure minimal set-up times for machining centers. Even components that are difficult to clamp mechanically are child's play with PLANOS, which holds them precisely and without deformation. - To increase the horizontal holding forces, the PLANOS matrix plates can be equipped with optional friction islands. In comparison with matrix plates without friction islands, the horizontal holding forces are up to 30% higher on matrix plates with friction islands.

- The PLANOS support plate in combination with suction cups is the optimal solution for 5-side machining and for the machining of workpiece cut-outs. The support plate can be easily fastened to the base plate.

-

SCHUNK Planos Vacuum table 600 mm X 400 mmX 28 mm

Regular price £1,900.00Regular priceUnit price / per -

SCHUNK Planos Vacuum table 600 mm X 400 mmX 28 mm (WITH FRICTION ISLANDS)

Regular price £2,540.00Regular priceUnit price / per -

SCHUNK Planos Vacuum table 400mm X300 mmX 28 mm

Regular price £1,480.00Regular priceUnit price / per -

SCHUNK Planos Vacuum table 400mm X300 mmX 28 mm (WITH FRICTION ISLANDS)

Regular price £2,000.00Regular priceUnit price / per -

SCHUNK Planos Vacuum table 300 mm by 200 mm by 28 mm

Regular price £790.00Regular priceUnit price / per