Knowledgebase

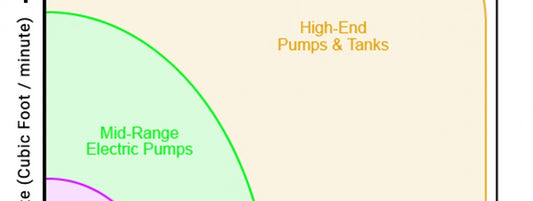

Which vacuum pump should I use?

This is probably the most common question I am asked and can get quite confusing. Here are 3 basic principles you can use to determine which vacuum pump will fit...

Which vacuum pump should I use?

This is probably the most common question I am asked and can get quite confusing. Here are 3 basic principles you can use to determine which vacuum pump will fit...

What vacuum table do I need?

This is a very common question I am asked. The simple answer is it just depends on what you are CNC machining and what results you wish to achieve. There...

What vacuum table do I need?

This is a very common question I am asked. The simple answer is it just depends on what you are CNC machining and what results you wish to achieve. There...

How does vacuum clamping work?

The Basic Principal of Vacuum Clamping First of all we find the normal atmospheric air pressure inside and outside of the vacuum table, which withholds approximately 1 bar. Next some...

How does vacuum clamping work?

The Basic Principal of Vacuum Clamping First of all we find the normal atmospheric air pressure inside and outside of the vacuum table, which withholds approximately 1 bar. Next some...

Liquid Ring Pumps

The liquid ring pump is a very useful device in the machining centre. It allows the machinist to work with fluids on all their parts be it mist cooling or...

Liquid Ring Pumps

The liquid ring pump is a very useful device in the machining centre. It allows the machinist to work with fluids on all their parts be it mist cooling or...

Vacuum table - Ral Pro Series

The RAL PRO vacuum table is manufactured from solid aluminium and is trued on both sides. As a result the maximum possible strength and freedom from distortion are guaranteed on...

Vacuum table - Ral Pro Series

The RAL PRO vacuum table is manufactured from solid aluminium and is trued on both sides. As a result the maximum possible strength and freedom from distortion are guaranteed on...

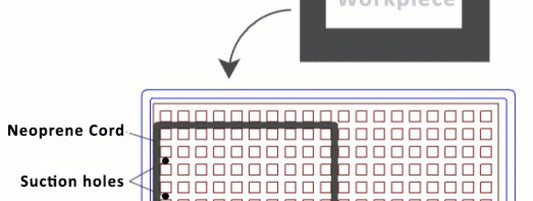

Vacuum table SEAL Series

Our SEAL Series vacuum tables are an advanced version of our ST Series vacuum tables. A 8 mm strong aluminum plate at the bottom of the vacuum table provides extra...

Vacuum table SEAL Series

Our SEAL Series vacuum tables are an advanced version of our ST Series vacuum tables. A 8 mm strong aluminum plate at the bottom of the vacuum table provides extra...